Kailash Rubber Industries was established in 1998, at Ahmedabad. Our company is also specialized in Dam Gate Rubber Seals & Printing Rubber Rollers. At KRI rubber seals are prepared by extrusion and moulding process. Developing full range of dam gate rubber seals z’ type rubber seal, musical knot type rubber seal (p type), L’type, hollow bulb type, mushroom type, c’ type, arrow type, double bulb type, double steam type, Teflon cladded type, brass cladded for radial gate, stop log gate, vertical gate, spill way gate etc.

All seals are made from Superior Rubber Compound it has been regularly tested and approved by Engineers. Every batch of mixed rubber undergoes rigorous testing at factory laboratory if required also at government or private sector laboratory to ensure all of the physical and chemical requirements before being released to final stage. KRI is also specialized in Rubber Rollers used in Printing Industries.

“Ready to Print” rollers are supplied with a new core machined on CNC lathes with very high tolerances. The core is dynamically balanced before and after the covering. Rollers are supplied fully assembled with fixtures and bearings. Kailash Rubber Industries develops complete range of offset printing products and can cater complete range of rollers, which are used for offset machine, tin printing, textile printing, lamination machine.

We can manufacture any moulding and extruded products adds up to a wide range of rubber items which includes Gasket, Bushes, Bellows, ‘O’ ring, U-Seal, V-seal, Grommet, Diaphragms, rubber to metal etc. We are able to design and manufacture prototype, production moulds and make dies in-house, resulting in low-cost tooling and fast delivery. With the input of many years in the business, we also enjoy assisting our customers in the design of rubber part for their specific application.

Kailash Systems Advantage stands for good services, high quality, more process-related reliability and increased profitability in printing. A complete and compatible product system from our laboratories assures our coustomer a consistent and controlled production process and superior print quality. Kailash Rubber have various type of moulds supplied for different types of water projects, hence it is advantageous to have a ready mould availability and quick production thus saving on the last minute call of the project. Customized requirements can be easily catered. Development is the key item for our company. Our company is engaged in manufacturing of unmatched quality rubber compound, different polymers such as Natural, Nitrile, Neoprene, EPDM, Haypolone, Butyl, Polyurethane, Silicon, Viton and many more.

⇒ Experienced R & D Department

⇒ Good Financial Position & TQM

⇒ Huge Product Line

⇒ Large Production Capacity

⇒ Superior quality of Packaging

⇒ Timely delivery of products

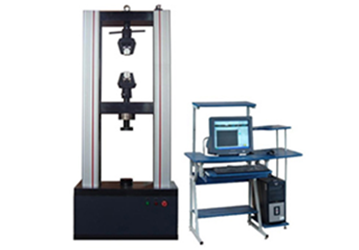

KRI has an in-house testing facility for verification and performance characteristics of its products. Our facilities have testing equipment’s like computerized Tensile Testing Machine, Hot Air Oven and different types of hardness testers with NABL certification. We also have arrangement of testing from government recognized laboratories for special characteristics of product as per customer requirement. Our company has developed more testing facilities for Abrasion Resistance by, DIN Abrasion Tester,TEFLON CLADDED RUBBER SEAL, DOUBLE BULB TYPE RUBBER SAEL.

Tags : Barrage Gate Rubber Seal Manufacturer in Ahmedabad, Radial Gates Rubber Seal Manufacturer in India, Radial Gates Rubber Seal Manufacturer in Madhyapradesh, Radial Gates Rubber Seal Supplier in Uttar Pradesh, Radial Gates Rubber Seal Supplier in Chattishgarh, Radial Gates Rubber Seal Supplier in Rajasthan, Radial Gates Rubber Seal Supplier in Delhi, Radial Gates Rubber Seal Supplier in Jharkhand

All Copyrights © 2024 Kailash Rubber Industries.

Powered by : :

Growup Business Solution - Best SEO

Company Ahmedabad